Here at Rampisham Hill Mill, we can offer individuals and businesses a tailored wool processing service using our dedicated sheep wool processing machinery, housed in a purpose built mill building on our farm. This enables us to control the whole process ourselves to meet your exact needs.

We can currently offer the following services:

SCOURING & OPENING

Your fibre will be skirted, tumbled, scoured and then opened before being returned, or further processed in the mill. By opening the fleece after scouring, a lot of the finer vegetation matter etc are removed from within the fleece (although we can’t remove it all), as well as it prepares the fleece to give a far higher quality fibre for carding, resulting in a smoother and cleaner output from the carder.

Scoured and Opened Romney Fibre

Picker – Opening Scoured Fibre

CARDING – (BATTS or SLIVER)

Having been scoured and opened, your fibre will be carded into BATTS of up to 1m wide (client to specify if it is to be different from our 60cm standard width) or drawn into SLIVER of specified weights and coiled ready for returning to the client, or being further processed in the mill.

Romney Batt & Sliver

Carding Dutch Spotted

Dutch Spotted Batt Rolling

Shetland Batts and Sliver in four natural colours

GILLING

Your fibre having been scoured, opened and carded into sliver will be processed through our gill. Here up to 8 cans can be drafted at once during each pass, aligning fibres parallel and allowing discrepancies in the sliver to be reduced. The gill is also used for breed or colour blending if required. The output from the gill is in the form of ROVING which are desired by hand spinners and clients will often have the fibre returned to them at this stage. We coil the roving into cans which can then be sent to our spinner. Most sliver will be passed several times through the gill to get a smooth and even roving.

Gilled Roving

Castlemilk Morit Roving

Shetland Roving

SPINNING

Having been scoured, opened, carded and gilled the fibre can be SPUN on our computer controlled 24 spindle machine to your requirements and then if required PLYED together.

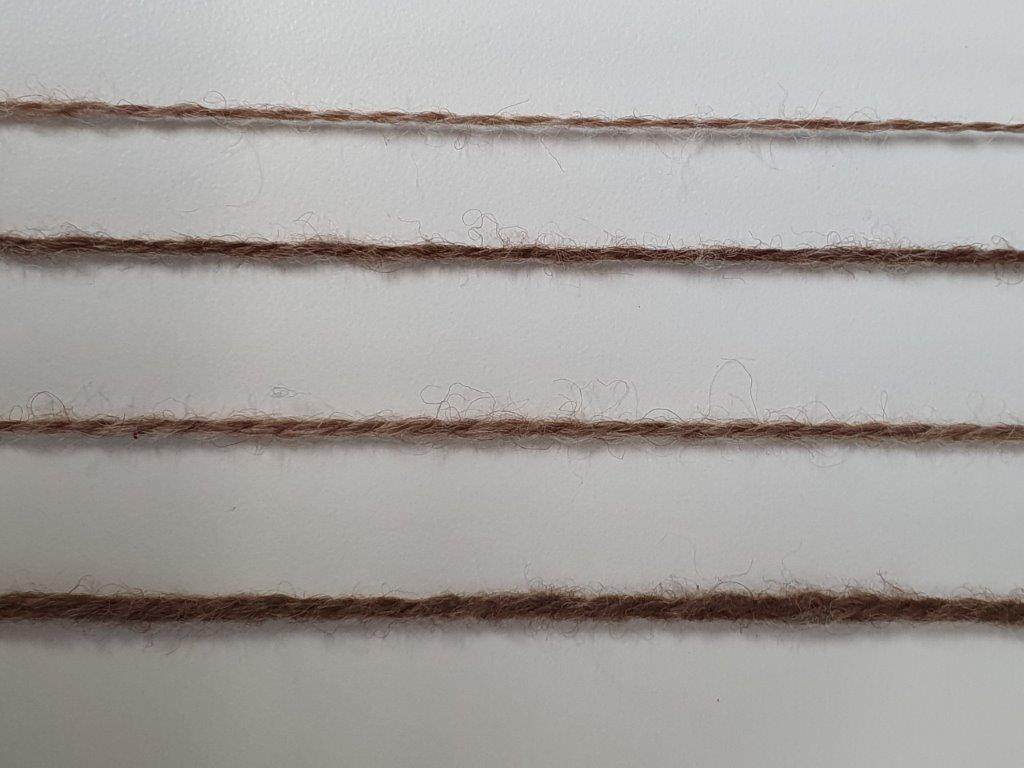

Romney Yarn

Spinning Shetland to 6nm

Plying Shetland

Shetland Yarn 4 Ply, DK, Aran & Chunky

FINISHING

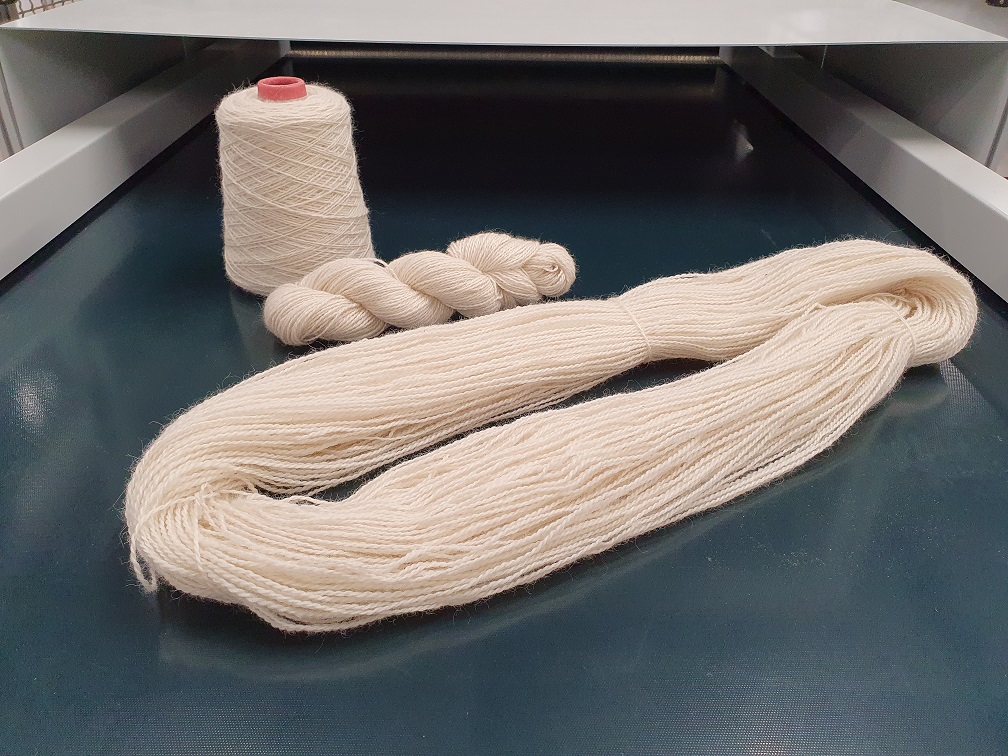

Your fibre having been spun can be taken from the spinning tubes and returned as HANKS, TWISTED SKEINS or wound onto CONES

Romney Cone, Twisted Skein & Washed Hank

Romney & Gotland Yarn

Shetland DK on Cones

Shetland Skeins